1. Approach to Climate Change Initiatives

1. Approach to Climate Change Initiatives

MISUMI Group Inc. announced its support for the TCFD recommendations in September 2021. That same month, the Company made an announcement to join the TCFD Consortium of companies that support the TCFD recommendations. MISUMI then began formulating strategies for climate change initiatives focusing on the Manufacturing Businesses, which have significant environmental impact. These initiatives include conducting an analysis based on the two scenarios of temperatures rising 1.5 to 2 degrees Celsius or temperatures rising 4 degrees Celsius, identifying transition risks, physical risks, and opportunities under each scenario and addressing the impacts on the businesses for each scenario.

MISUMI has disclosed information according to the TCFD recommendations under its management policy, based on the details approved by the MISUMI Board of Directors on March 17, 2022. This information includes the establishment of risk management processes for risk identification, assessment, and mitigation, quantified risk and opportunity assessments, and action to establish a progress assessment mechanism.

Going forward, MISUMI will fully disclose information related to climate change, in line with the TCFD framework, and through our business activities, we will act to counter climate change by mitigating global warming and contribute to the development of a sustainable society.

About the TCFD (Task Force on Climate-related Financial Disclosures)

The task force was established by the Financial Stability Board (FSB) in response to a request from the G20. The TCFD's purpose is to monitor and disclose the financial impact of the risks and opportunities brought about by climate change. In June 2017, it announced recommendations on how to voluntarily disclose information.

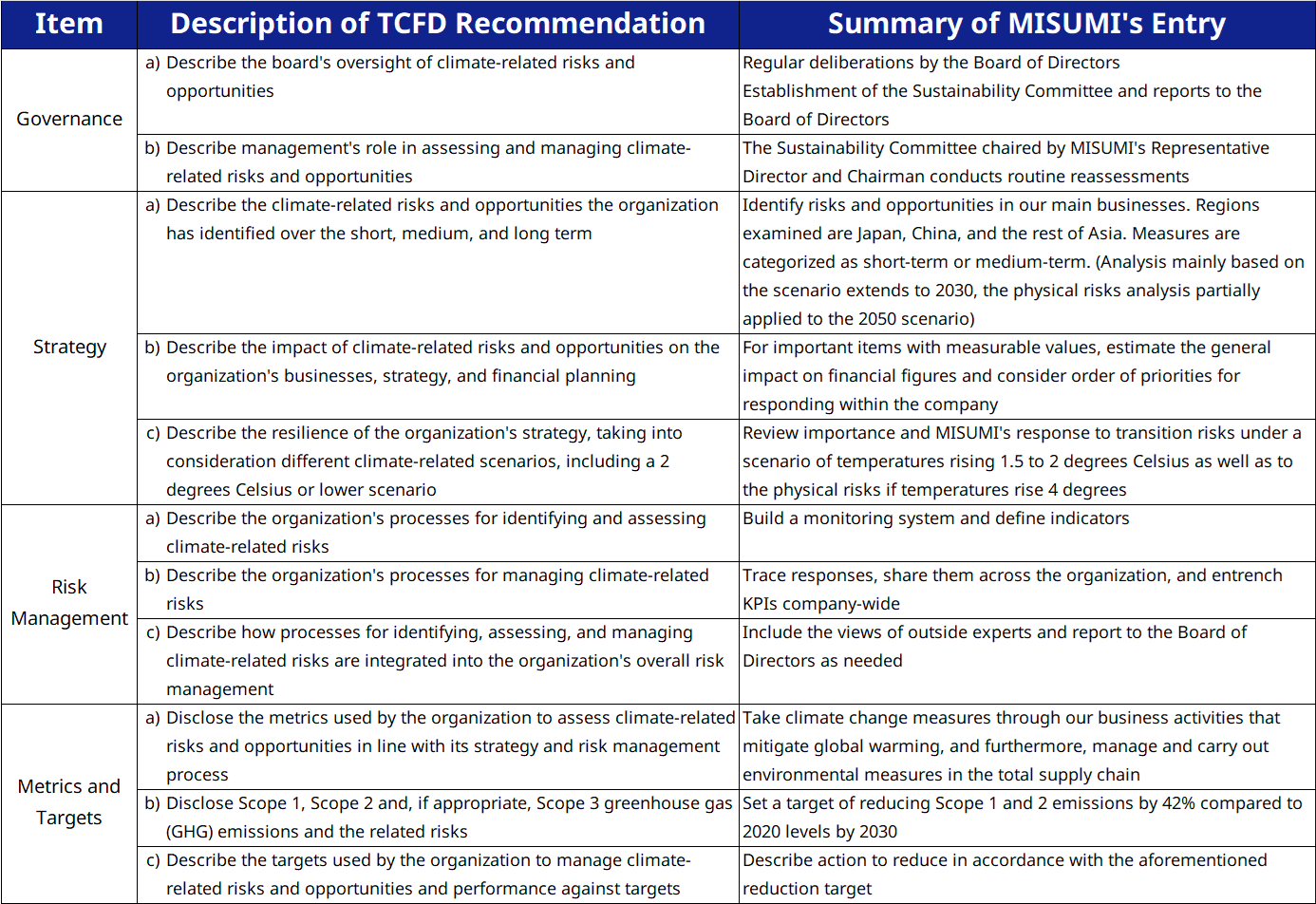

2. TCFD Framework and Comparison Table

2. TCFD Framework and Comparison Table

The table below compares recommended disclosures and the entries in MISUMI's disclosures.

Governance

Governance

3. Governance

3. Governance

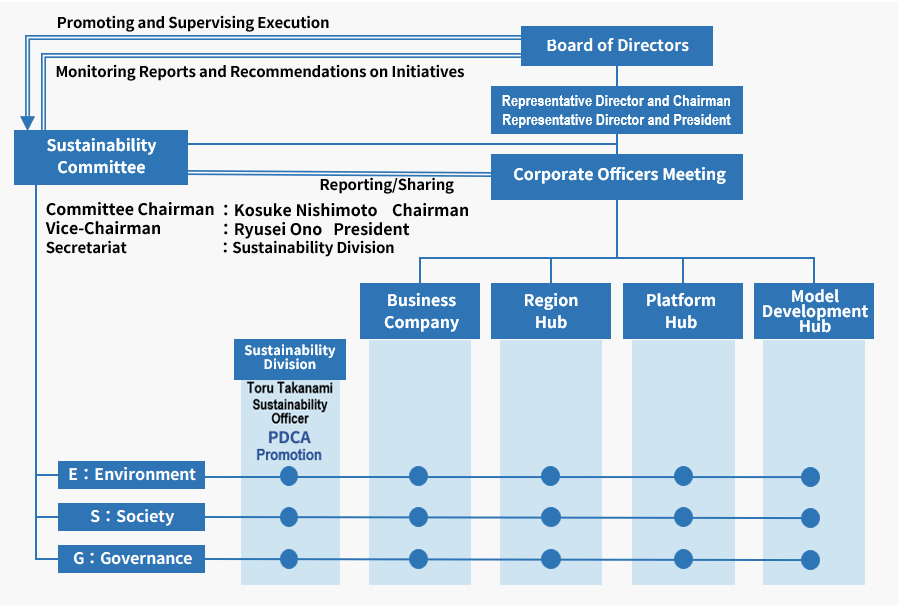

The MISUMI Board of Directors routinely reviews and discusses strategic measures to address climate change.

In October 2021, the Sustainability Committee was established, chaired by the Representative Director and Chairman, with the Representative Director and President serving as Vice-Chairman. This committee formulates basic sustainability policies, verifies them against management plans and policies, promotes initiatives to address social issues, and provides reports and recommendations to the Board of Directors.

To promote sustainability management across the entire Group, the Sustainability Committee, under the supervision of the Board of Director, appoints an Officer responsible for promoting sustainability. This Officer works in collaboration with the Group’s executive organizations—including the Business Company, Region Hub, Platform Hub, and Model Development Hub—to set goals, monitor progress, and evaluate initiatives related to Environmental, Social, and Governance (ESG) issues, thereby continuously advancing these efforts.

The Sustainability Division, which serves as the organization driving Company-wide efforts, identifies key ESG issues, including those related to climate change. It collaborates not only with Japan-based staff but also with representatives in China, Asia, Europe, and the Americas to formulate policies addressing regional challenges. Progress on these initiatives is reported to the Group's Corporate Officers meeting and the Sustainability Committee.

Going forward, the Sustainability Committee will conduct discussions to reassess climate change-related risks at least twice a year and report findings to the Board of Directors.

(Sustainability Management Structure)

(Sustainability Management Structure)

Strategy

Strategy

4. Approach to Producing the Report

4. Approach to Producing the Report

The Board of Directors approved the Basic Policy of Sustainability in December 2021. By eliminating waste of all types among our customers and suppliers, MISUMI’s business contributes to eliminating inefficiencies in the industrial automation industry. The industrial automation industry promotes labor-saving in a variety of business activities, thus making an essential contribution to society’s sustainable development. Meanwhile, MISUMI considers climate change measures to be one of the highest priority issues towards achieving society’s sustainable development and has taken action on this issue.

After endorsing the TCFD recommendations in September 2021, MISUMI exchanged ideas with outside experts while identifying business risks and opportunities and analyzing scenarios. MISUMI drafted a report based on numerous discussions with those tasked with carrying out operations both from a business perspective and from a business foundation perspective in terms of IT, production, and logistics. This report was then submitted to and deliberated by the Board of Directors.

4-(1) Identifying Risks and Opportunities

4-(1) Identifying Risks and Opportunities

MISUMI applied multiple scientific models of climate change to assumptions about future business, then analyzed the impact that both risks and opportunities will exert on strategy under each scenario.

We considered two scenarios. Under one, temperature increases will be contained to 1.5 to 2 degrees Celsius as society in general enacts change toward decarbonization. The other scenario assumes priorities placed on economic development will continue to have a negative impact and global temperatures will rise by 4 degrees Celsius. We then applied the results across the entire value chain and supply chain associated with our business activities.

We listed the risks of climate change responses extracted from each business segment. We consider risks with particularly large financial effects, as well as risks that have little temporary financial impact but continue for a long time, as most critical, and we discussed individual responses to each.

An overview follows.

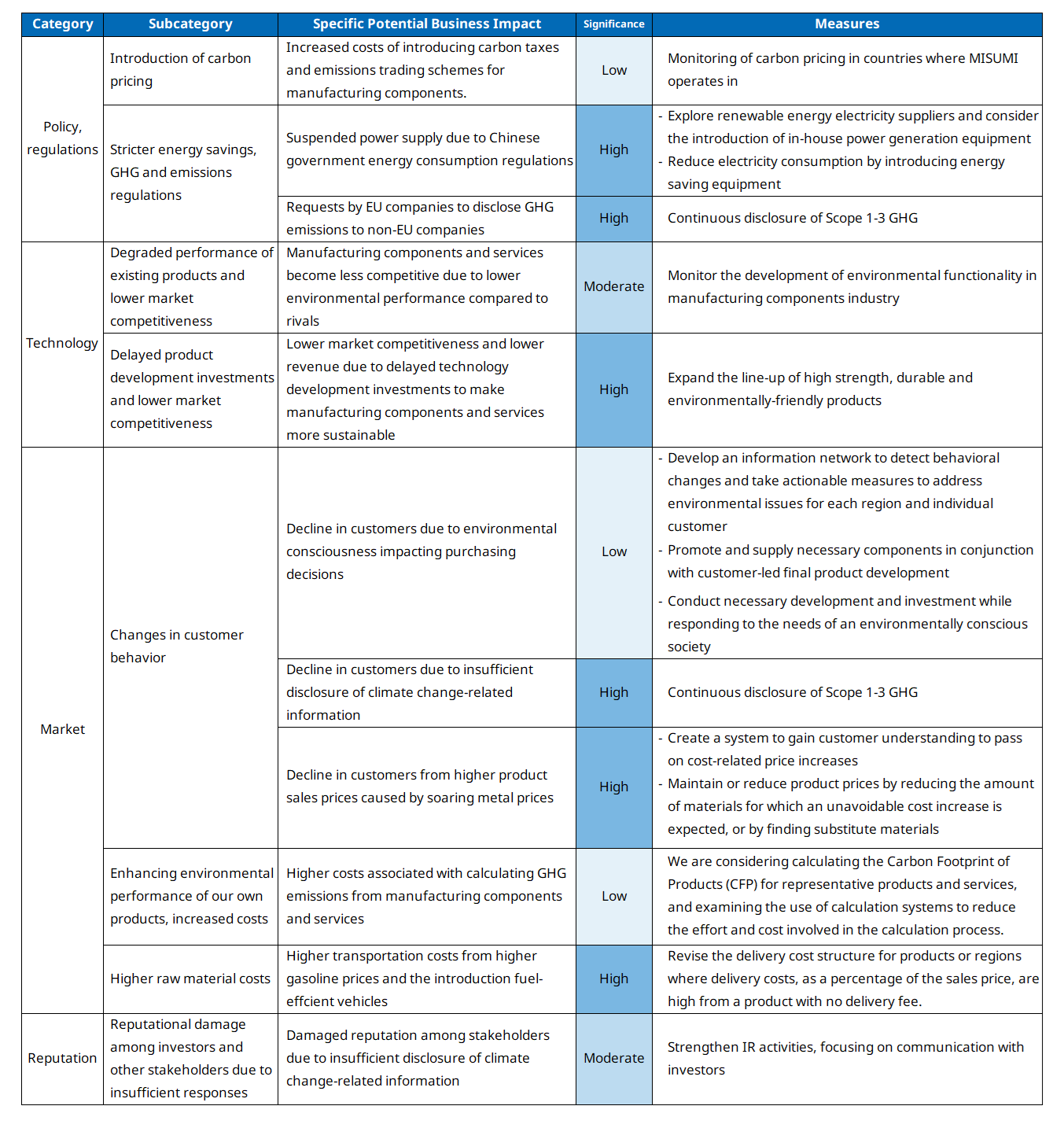

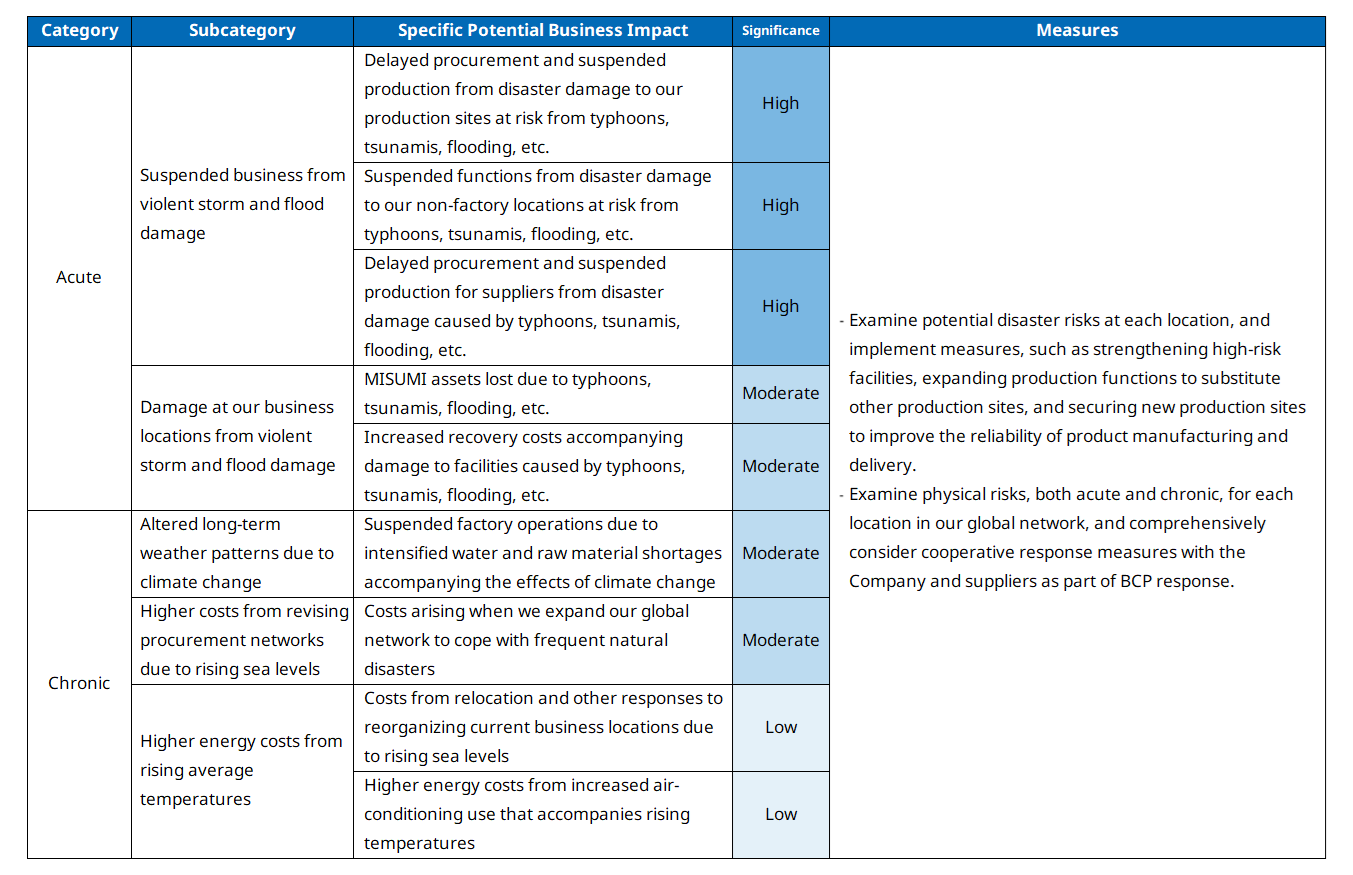

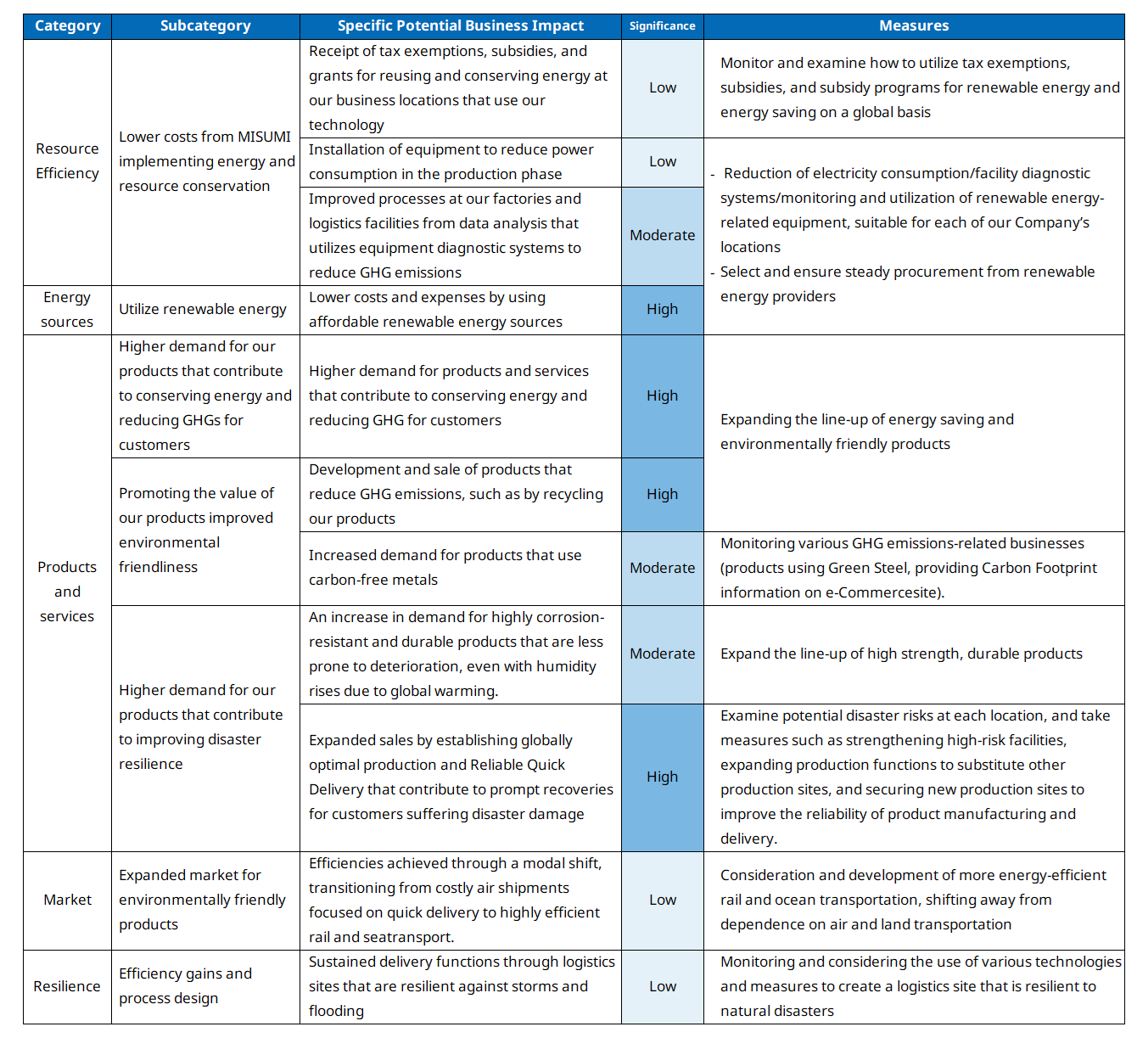

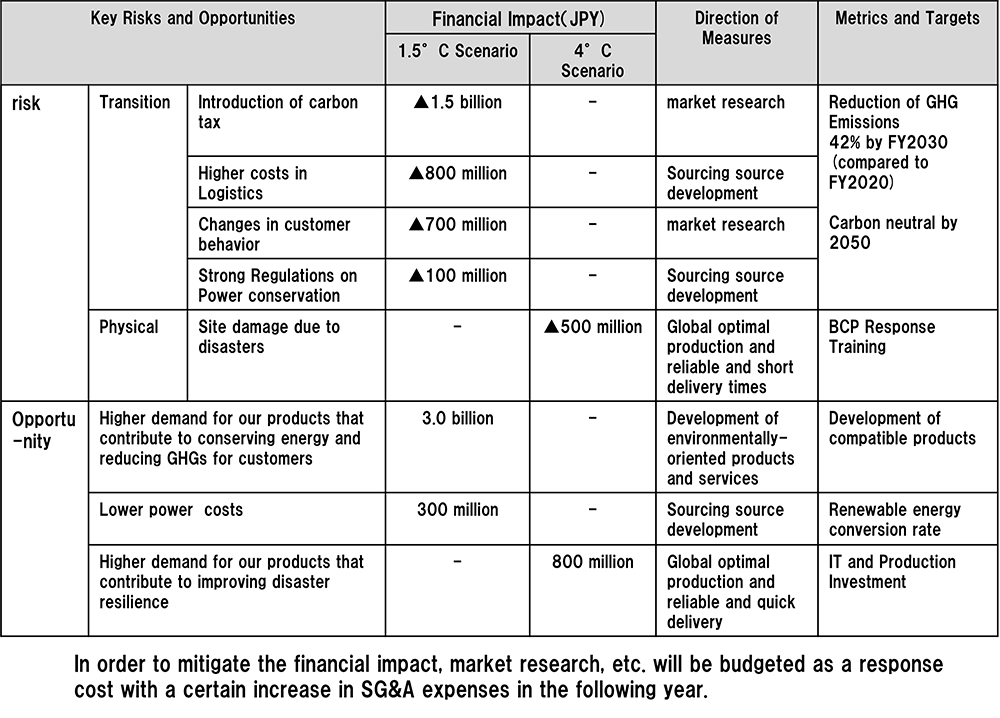

4-(2) Transition Risks

4-(2) Transition Risks

MISUMI recognizes major risks including increased sales prices and transportation expenses due to power consumption constraints and rate hikes; reputational damage from insufficient disclosure of information relating to greenhouse gas (GHG) emission reductions.

4-(3) Physical Risks

4-(3) Physical Risks

Although we anticipate extensive damage to our business locations, we are mitigating our risks by deploying production in multiple locations.

Conversely, MISUMI procures from over 3,000 product suppliers, some of whom lack comprehensive disaster plans. Consequently, we recognize the risk of potential product shortages in the event of a disaster.

4-(4) Opportunities

4-(4) Opportunities

MISUMI views changes to products and production processes for customers’ decarbonization as a future opportunity to expand sales. Furthermore, the Business MODEL MISUMI has built can contribute to strengthening social resilience against natural disasters.

5. Scenario

5. Scenario

5-(1) Scenario: Temperatures 1.5-2 Degrees

5-(1) Scenario: Temperatures 1.5-2 Degrees

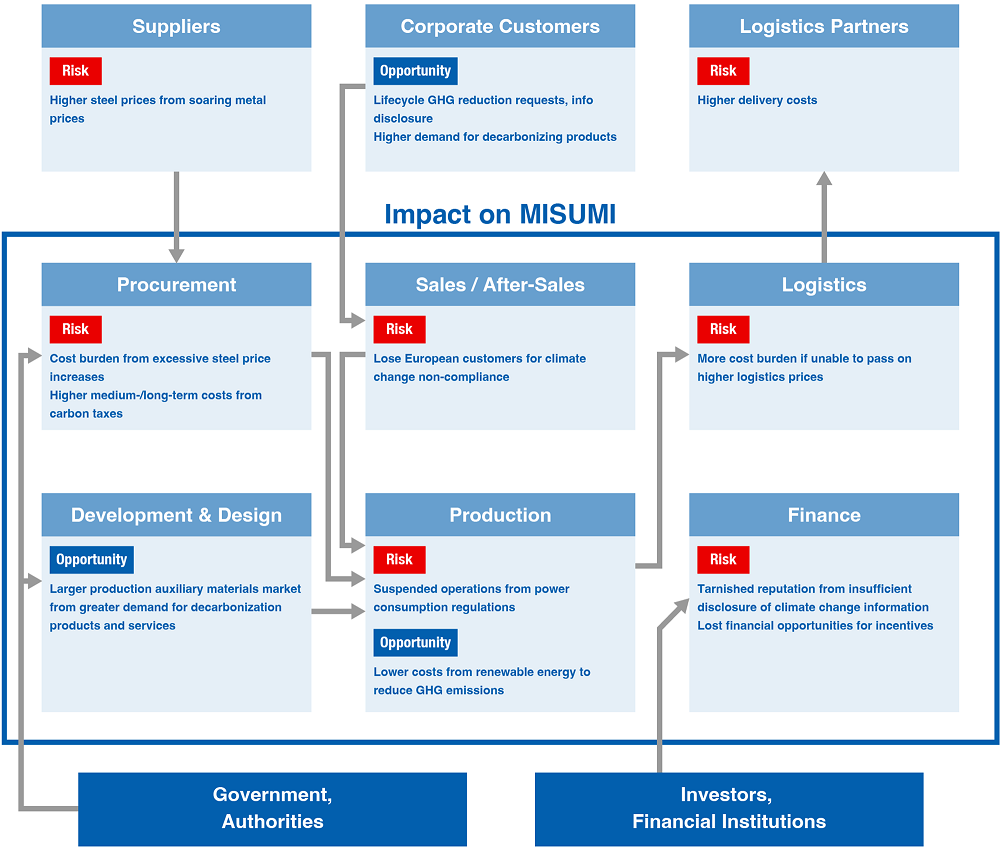

An analysis of a scenario in which temperatures rise 1.5 to 2 degrees Celsius shows that our industry would also be affected by national decarbonization policies in response to the rising temperatures.

First of all, a zero-carbon society would likely impose a greater burden. Although our main products would incur some degree of carbon taxation, we believe this would be limited due to the nature of the products.

On the other hand, with regard to stronger energy conservation regulation we have seen from governments in China and elsewhere, if a company with locations in the area were to be subject to an order to stop supplying power or suspend a project, our global network of locations for sales, logistics, and production facilities may have to reduce or halt operations. Among our primary customers like the automotive industry, there is progress in disclosing information and requesting reductions concerning greenhouse gas emissions. A slow response to this development could mean we fail to meet customers’ purchasing criteria, or there could be a risk of damage to our trustworthiness and reputation among investors and other stakeholders. Elsewhere, we expect the decarbonization trend to boost demand for electronic appliances and lightweight products and to significantly increase costs for the raw materials in our products. In addition, quickly rising fuel costs and the introduction of technology like EV trucks could impact our delivery cost structure. If temperatures rise 1.5 to 2 degrees Celsius, customers may change their purchasing decisions while society and industry in general maintain climate change measures. We expect higher demand from customers for efficiency such as labor productivity reforms and energy cost reductions.

If temperatures rise 1.5 to 2 degrees Celsius, customers may change their purchasing decisions while society and industry in general maintain climate change measures.

We expect higher demand from customers for efficiency such as labor productivity reforms and energy cost reductions.

MISUMI Group’s Business MODEL encourages a faster transition to a circular society by eliminating excess production and idle time at our customers’ worksites. Improving the Business MODEL with MISUMI Group’s advantage of Reliable, Quick Delivery will support the sustainable development of the entire IA industry.

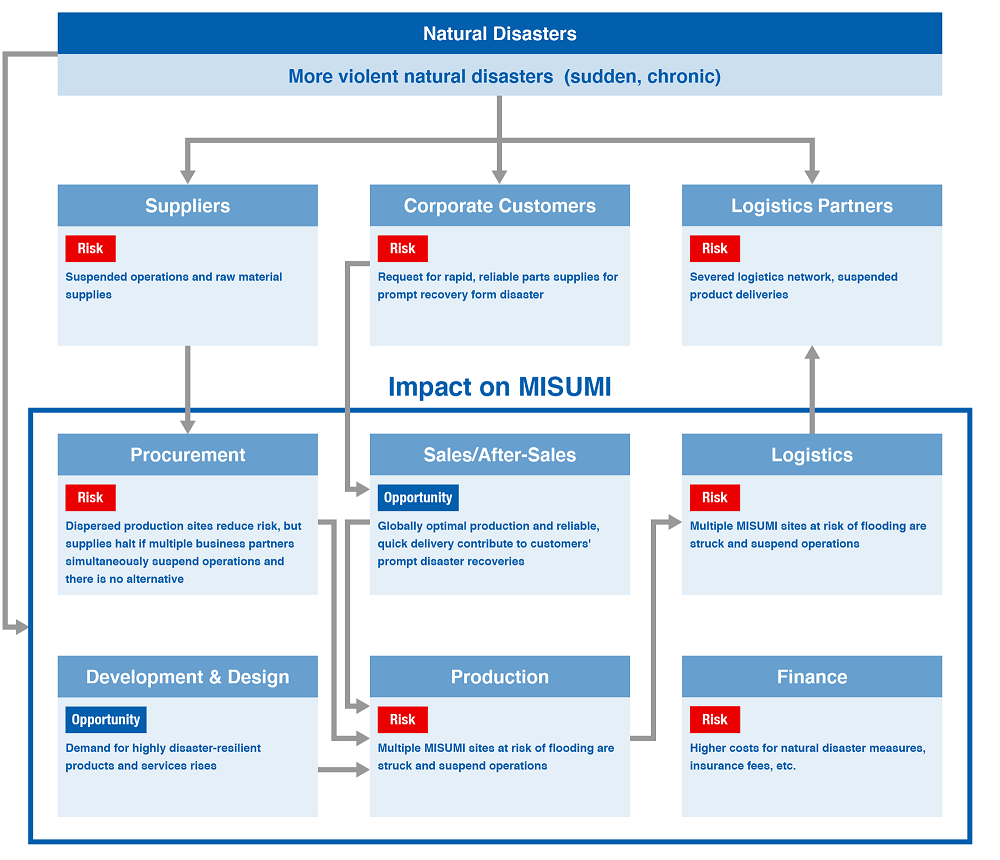

5-(2) Scenario: Temperatures 4 Degrees

5-(2) Scenario: Temperatures 4 Degrees

An analysis of a scenario in which temperatures rise 4 degrees Celsius shows decarbonization policies would not strengthen, average temperatures would continue to rise, and natural disasters would become more destructive, thus raising physical risks.

Our Company operates not only in Japan, but also in China, Asia, Europe, and the Americas, and building global network around the world. If a location were to be struck by a natural disaster such as a typhoon or flood, operations maybe suspended and assets such as our product and semi-finished product inventory, machinery, and logistics equipment maybe damaged. The globally optimal production and Reliable, Quick Delivery MISUMI has developed could also connect to a response to these risks. In addition, we believe that demand from customers and industry will increase for products and services that stand up well to temperature increase measures and disasters.

Globally optimal production is a system we built to disperse production sites around the world for optimization that determines what site will produce a customer’s order when it is received. Therefore, the production system is designed to be resilient during disasters and Reliable, Quick Delivery is a system we built to significantly reduce customer time and effort involved in placing orders and to reliably meet deadlines. We believe it can contribute to prompt reconstruction and recovery for industry in general during disasters.

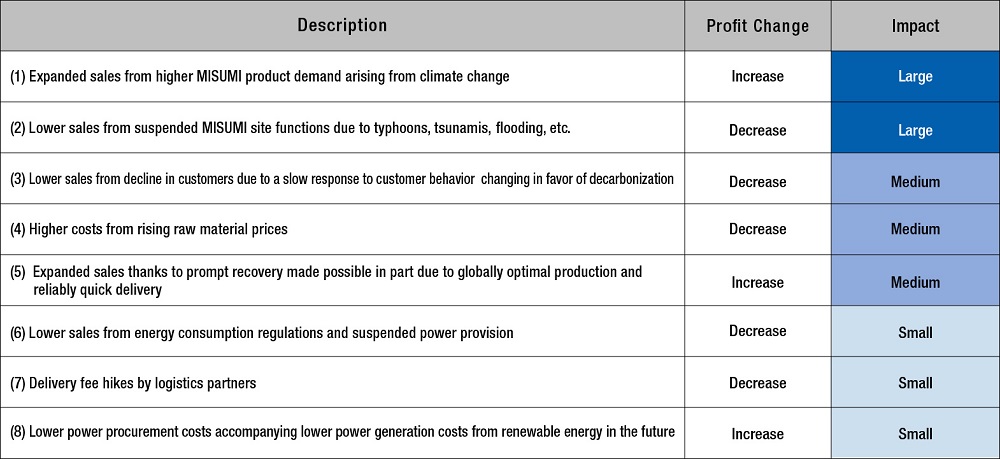

6. Business Impact Assessment

6. Business Impact Assessment

We assessed the impact each scenario would have on the organization's strategic and financial positions. We analyzed the risks and opportunities projected to have a relatively large financial impact.

Risk Management

Risk Management

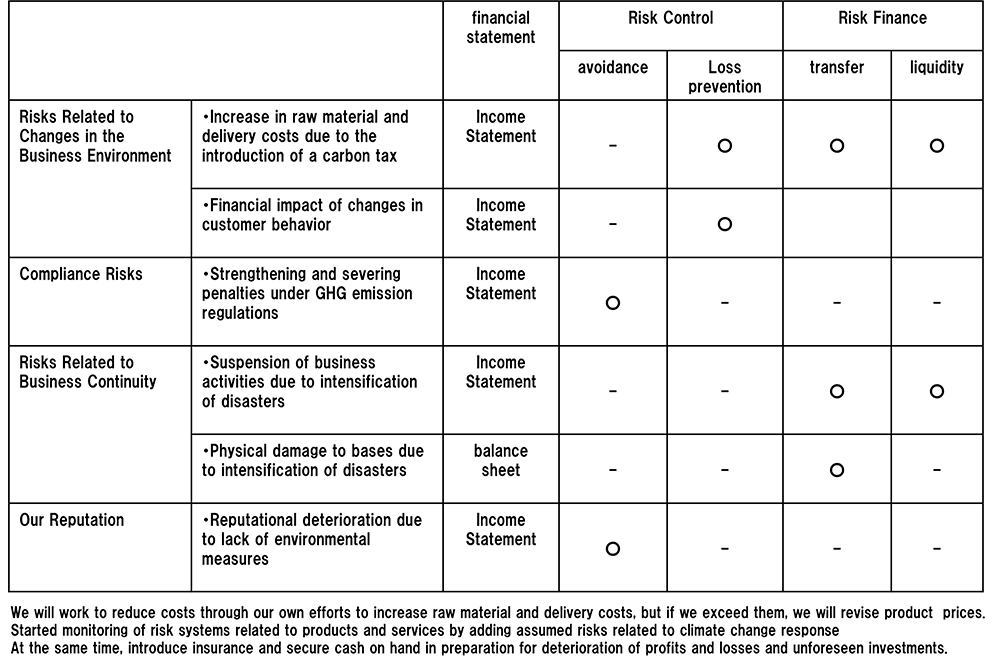

7. Risk Management Process

7. Risk Management Process

Risks are prioritized based on the likelihood, magnitude, and timing of financial impact. We are building a risk management system that focuses on the fact that the amount of GHG emissions associated with our customers’ energy use is relatively high compared to our Company.

Our Company conducts a risk assessment once a year of Business Companies, Headquarters and Platforms that execute operations. We report significant cases and management issues to the Board of Directors. Climate change has also been identified as a high-priority risk.

In areas where damage from storms and flooding is expected, we are strengthening the resiliency of our facilities and conducting training focused on employee and facility safety. Meanwhile, in areas that have experienced little such risk or where risk is difficult to predict, we focus on daily monitoring while striving to minimize disaster damage and ensure rapid recovery.

The Sustainability Committee takes an integrated approach to managing climate change risks by setting targets, monitoring progress, and conducting assessments. As needed, the Committee draws on the opinions of outside experts and reports to the Board of Directors.

The Company has built a structure for BCP (Business Continuity Plan) based on the possible impacts of major disasters increasing in severity.

Alongside our existing corporate entity in Japan, we have implemented a comprehensive system of documentation, processes, and communication methods for disaster countermeasures at our overseas subsidiaries.

In preparation for physical risks such as severe storm and flood damage, we will enhance these systems and conduct necessary training.

We shared our internally developed “Sustainable Procurement Guidelines” with primary suppliers in Japan and requested their endorsement.

In addition, we conducted a survey to collect information on their environmental initiatives, including greenhouse gas (GHG) emissions and the development status of their management systems, in order to conduct a comprehensive fact-finding investigation.

We aim to fulfill our social responsibility throughout the supply chain by building mutual trust with our suppliers.

Metrics and Targets

Metrics and Targets

8. Metrics and Targets

8. Metrics and Targets

Through its business, MISUMI Group provides customers with added value that reduces the quantity of invested resources and consumption related to Industrial Automation. We believe that fundamentally eliminating inefficiencies in our customers’ operations will help accelerate the transition from the conventional economy of mass production, mass consumption, and mass disposal to a circular economy.

Moreover, we actively engage in climate change initiatives, including global warming prevention, through our business operations.

We also advance environmental management throughout the entire supply chain, encompassing suppliers, with a focus on executing environmental measures and ensuring product quality and safety.

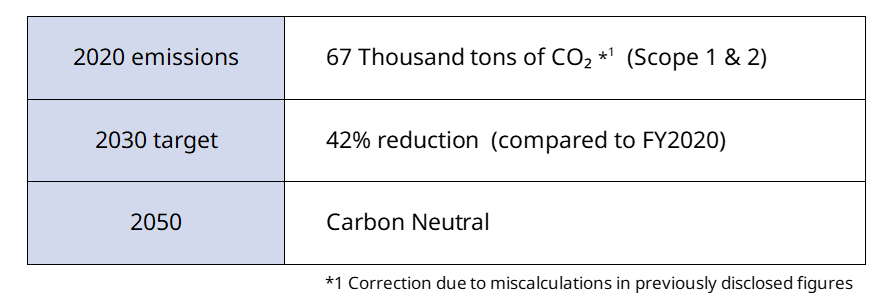

8-(1) Carbon-Neutral Plan and Implementation Measures

8-(1) Carbon-Neutral Plan and Implementation Measures

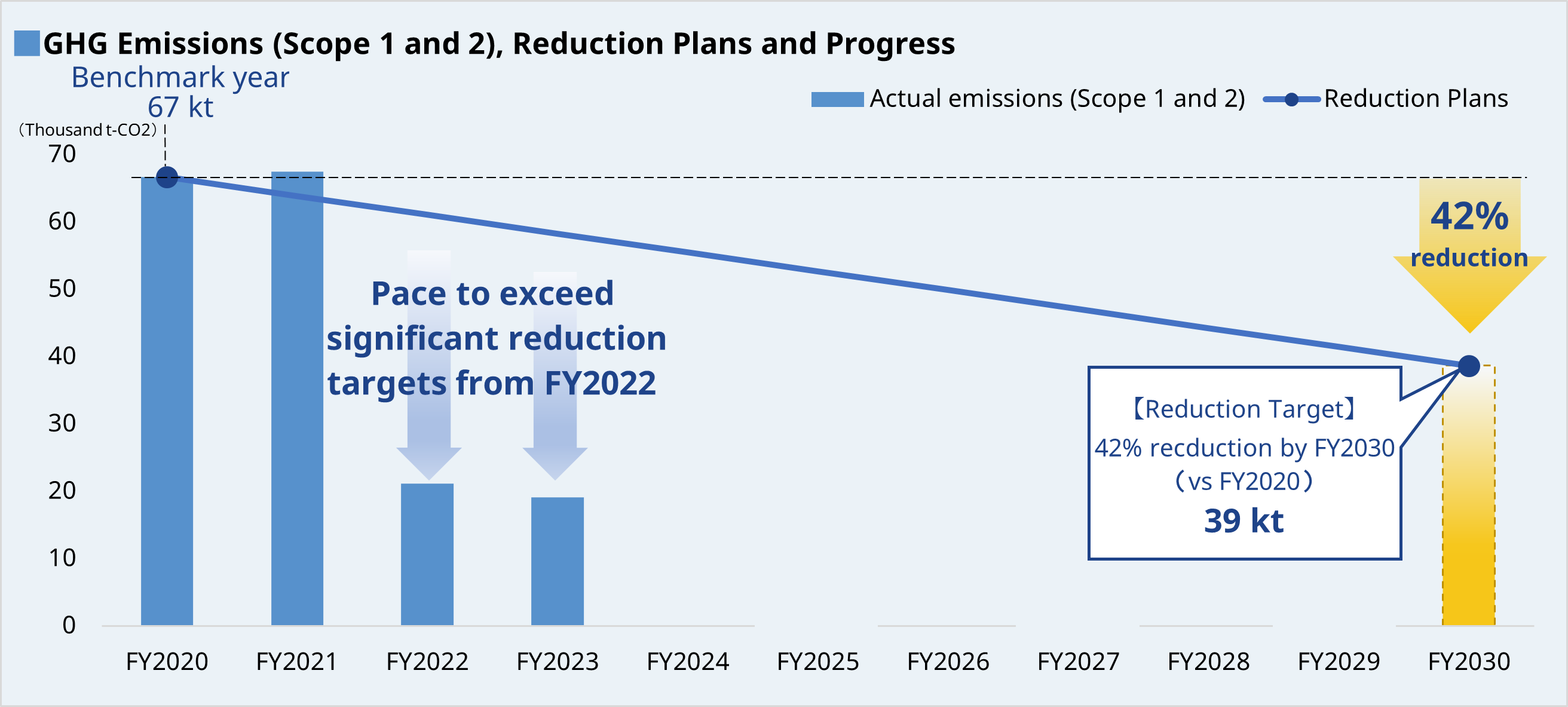

MISUMI Group's goal is to achieve carbon neutrality by 2050. To this end, we have established targets to reduce Scope1 and Scope2 GHG emissions by 42% by FY2030, compared to FY2020 base year levels.

Transition in GHG emissions and reduction target of MISUMI Group

Transition in GHG emissions and reduction target of MISUMI Group

To achieve these targets MISUMI group is focusing on the following as our three key initiatives to reduce GHG:

- Various energy-saving activities

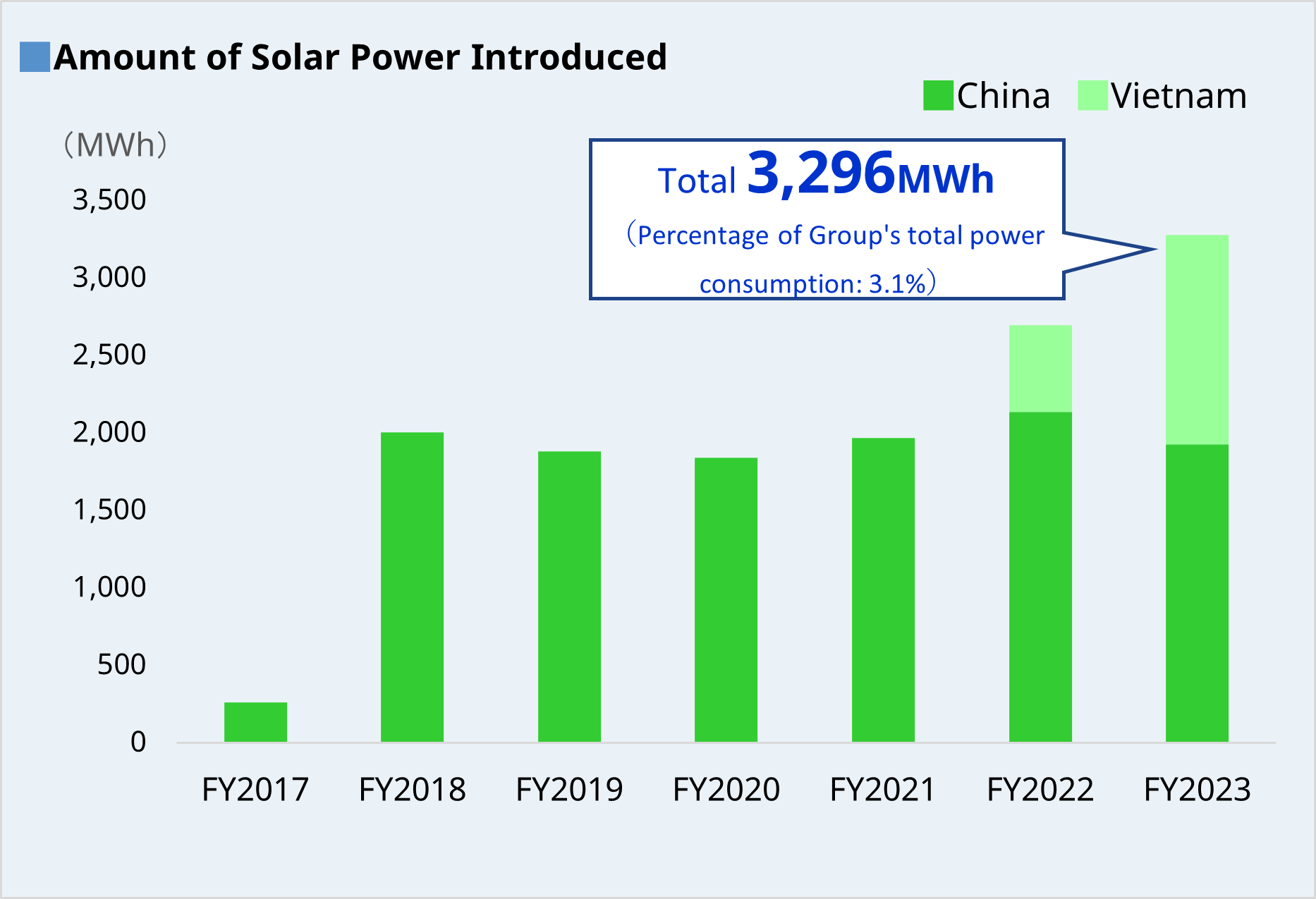

- Initiatives to generate renewable energy ("Producing renewable energy") through means such as solar/PV power generation

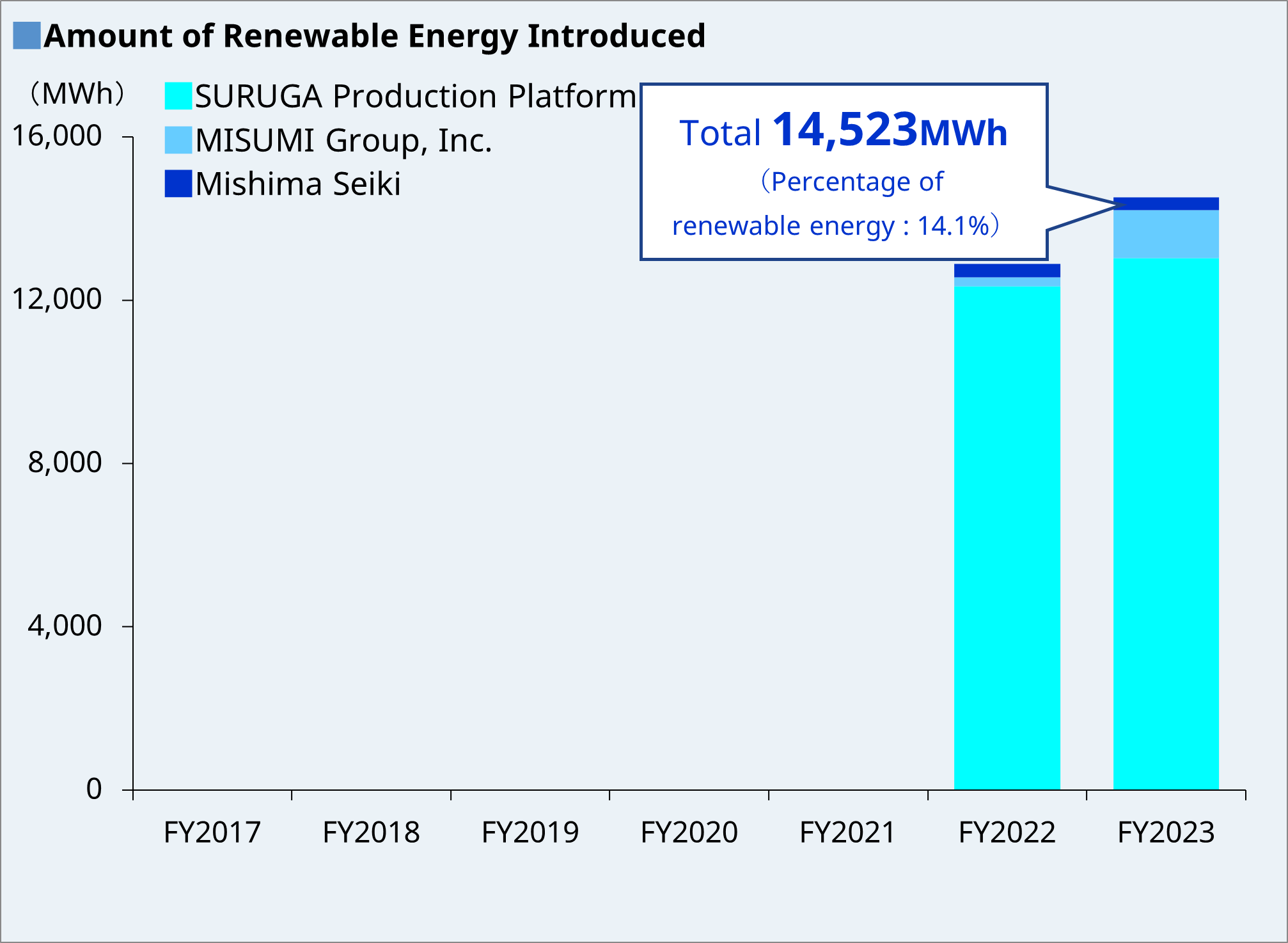

- Introducing renewable energy, such as purchasing renewable electric power and/or renewable energy certificates, including I-REC, TIGR, etc.

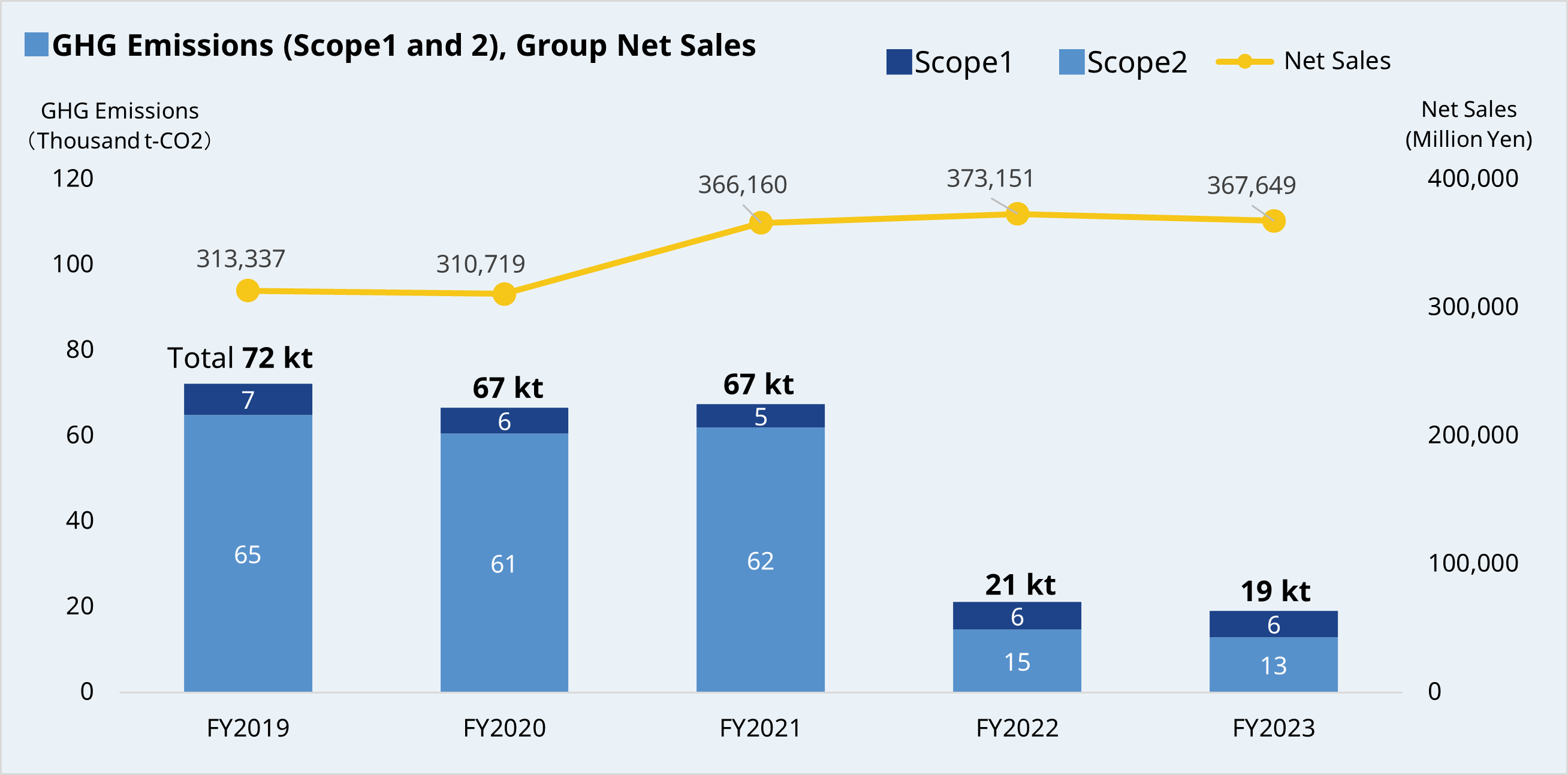

Greenhouse Gas(GHG) Emissions

Greenhouse Gas(GHG) Emissions

Energy consumption and greenhouse gas (GHG) emissions of MISUMI Group

| Input | Unit | FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|---|---|---|

| Energy Consumption | Grid-connected electric power | MWh | 118,860 | 111,923 | 114,831 | 109,213 | 103,086 | 103,107 |

| Gasoline | ㎘ | 810 | 576 | 473 | 635 | 843 | 778 | |

| Diesel | ㎘ | 353 | 347 | 319 | 419 | 315 | 234 | |

| Kerosene | ㎘ | 9 | 14 | 11 | 6 | 7 | 7 | |

| LPG | t | 46 | 32 | 47 | 55 | 57 | 51 | |

| LNG | t | 0 | 0 | 0 | 0 | 0 | 0 | |

| Natural gas | Thousand m3 | 1,317 | 1,184 | 1,010 | 1,156 | 1,096 | 1,235 | |

| City Gas | Thousand m3 | 610 | 506 | 518 | 511 | 461 | 487 | |

| Other supplied energy (including steam, hot water) | GJ | 9,577 | 8,545 | 6,833 | 6,978 | 6,847 | 7,006 | |

| Amount of Onsite Solar Power Introduced | MWh | 1,883 | 1,841 | 1,936 | 2,698 | 3,296 | 6,172 | |

| Amount of Carbon Neutral Electricity Introduced (Other than Onsite Solar Power) | MWh | 0 | 0 | 0 | 12,940 | 14,731 | 15,936 | |

| Output | Unit | FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| CO2 emissions | Scope1 | Thousand t-CO2e | 7 | 6 | 5 | 6 | 6 | 6 | ||

| Scope2 | Thousand t-CO2e | 65 | 61 | 62 | 15 | 13 | 12*2 | |||

| Scope3 | Thousand t-CO2e | 1,524 | 1,399 | 1,637 | 1,528 | 1,353*1 | 1,424 | |||

| Scope3 Itemization (Category) | ||||||||||

| 1 | Purchased goods and services | Thousand t-CO2e | 1,350 | 1,258 | 1,463 | 1,346 | 1,160*1 | 1,244 | ||

| 2 | Capital goods | Thousand t-CO2e | 58 | 45 | 53 | 44 | 58 | 49 | ||

| 3 | Fuel- and energy-related activities not included in Scope 1 or Scope2 | Thousand t-CO2e | 11 | 10 | 10 | 9 | 8 | 8 | ||

| 4 | Upstream transportation and distribution | Thousand t-CO2e | 87 | 73 | 96 | 112 | 108 | 98 | ||

| 5 | Waste generated in operation | Thousand t-CO2e | 3 | 3 | 3 | 3 | 3 | 4 | ||

| 6 | Business travel | Thousand t-CO2e | 7 | 1 | 2 | 3 | 6 | 8 | ||

| 7 | Employee commuting | Thousand t-CO2e | 3 | 3 | 3 | 3 | 3 | 3 | ||

| 8 | Upstream leased assets | Thousand t-CO2e | - | - | - | - | - | - | ||

| 9 | Downstream transportation and distribution | Thousand t-CO2e | - | - | - | - | - | - | ||

| 10 | Processing of sold products | Thousand t-CO2e | - | - | - | - | - | - | ||

| 11 | Use of sold products | Thousand t-CO2e | - | - | - | - | - | - | ||

| 12 | End-of-life treatment of sold products | Thousand t-CO2e | 6 | 6 | 7 | 7 | 8 | 8 | ||

| 13 | Downstream leased assets | Thousand t-CO2e | - | - | - | - | - | - | ||

| 14 | Franchises | Thousand t-CO2e | - | - | - | - | - | - | ||

| 15 | Investments | Thousand t-CO2e | - | - | - | - | - | - | ||

| Total (Scope1+2+3) | Thousand t-CO2e | 1,597 | 1,465 | 1,704 | 1,549 | 1,372*1 | 1,441 | |||

・The facts contributing to the reduction in Scope 2 emissions in FY2022 compared to the previous year are as follows:

- ・Introduced solar photovoltaic power system at our production site in Vietnam

- ・Promoted energy conservation related to air conditioning at our domestic production site (Shizuoka).

- ・Introduced CO2-free electricity at domestic production sites and our Head Office building.

- ・Purchased renewable energy certificates (I-REC, GEC) for our production sites in Vietnam, China, Thailand, and India.

The correct results for fiscal year 2024 are as follows: Scope 1 emissions: 6 thousand t-CO₂e, Scope 2 (market-based) emissions: 12 thousand t-CO₂e, and combined Scope 1+2 emissions: 18 thousand t-CO₂e.

The figures published on this page represent the accurate values.

Compared to the base year (fiscal year 2020), we have achieved a reduction of approximately 74%. (Our target is a 42% reduction compared to the base year by fiscal year 2030.)

Target to reduce our GHG emissions

Target to reduce our GHG emissions

We have set a target to reduce our GHG emissions as below. This target is aligned with the reduction ratio/level defined by SBTi (*1) in its 1.5℃ scenario (*2).

【Target】

【Target】

We plan to reduce our GHG emissions regarding our groupwide/global activities (Scope1,2) as follows;

-

In FY2030: 42% reduction compared to FY2020

-

In FY2050: To be Carbon Neutral

- *1

-

SBTi (Science Based Targets initiative) is an initiative to promote business entity to set GHG reduction targets, that is in alignment with the level that Paris Agreement (of COP21 in 2015) aims for.

- *2

-

1.5℃ scenario is a target, that is defined in Paris Agreement, to limit an average of the rise in global temperature to 1.5 degree Celsius from pre-industrial baseline.

Reduction plans and Progress

Reduction plans and Progress

To achieve our GHG reduction targets (of Scope1 & 2), we have planned annual reductions until FY2030 as shown in the chart below.

Currently, we have achieved a significant reduction starting from FY2022, and are progressing at a pace that exceeds our initial targets.

Details regarding the factors contributing to these reductions are provided in the following section on the reduction results.

Measures and results of our GHG reduction

Measures and results of our GHG reduction

Since FY2022, we have achieved significant reductions in greenhouse gas (GHG) emissions (Scope 1 and 2), with total Group emissions standing at 48 Thousand t-CO₂ (*5) for FY2023, a 71% (*5) decrease compared to FY2020. Specifically, we introduced solar power generation equipment at our production site in Vietnam (Onsite PPA *1), promoted a variety of energy conservation activities at our domestic and overseas production sites, introduced CO₂ -free electricity (*2) at domestic production sites and our Head Office building, and purchased renewable energy certificates (I-REC, TIGR, etc.*3) for our main production sites in Vietnam, China, Thailand, and India.

Also, we have partially adopted calculations based on “primary-data-based emissions” (*4) for Scope 3 Category 1 and have requested our major suppliers to disclose their GHG emissions.

*1 We have introduced Onsite PPAs for solar power at our Nantong Factory in China and SAIGON PRECISION in Vietnam.

Onsite PPA (Power Purchase Agreement) is a contractual arrangement in which a company has another company construct, own, operate, and maintain power generation facilities on its land, and the Company purchases the electricity generated from said power generation facilities.

*2 Since FY2022, we have started to use CO₂-free electricity at domestic manufacturing sites and the Head Office building. The domestic sites are SURUGA Production Platform’s Shimizu Factory, Ami Factory, Kansai Factory, and Mishima Seiki. The Head Office building is located in Kudan Kaikan Terrace and includes MISUMI Group Inc. and a portion of MISUMI Corporation.

- *3

-

I-REC (International Renewable Energy Certificate) is a renewable electricity certificate certified and issued based on the rules and system provided by the I-REC Standards Foundation (the Netherlands). TIGR (Tradable Instrument for Global Renewables) is a renewable energy certificate certified and issued under the rules and system provided by APX (USA). The I-REC and TIGR certificates purchased by MCC are limited to renewable electricity generated within each country's market.

- *4

-

Primary-data based emissions: Emissions that are based on the data obtained directly from business partners and are not calculated with the spend-based method (secondary emission factors provided by the Ministry of the Environment are not used)

- *5

-

Correction due to miscalculations in previously disclosed figures.

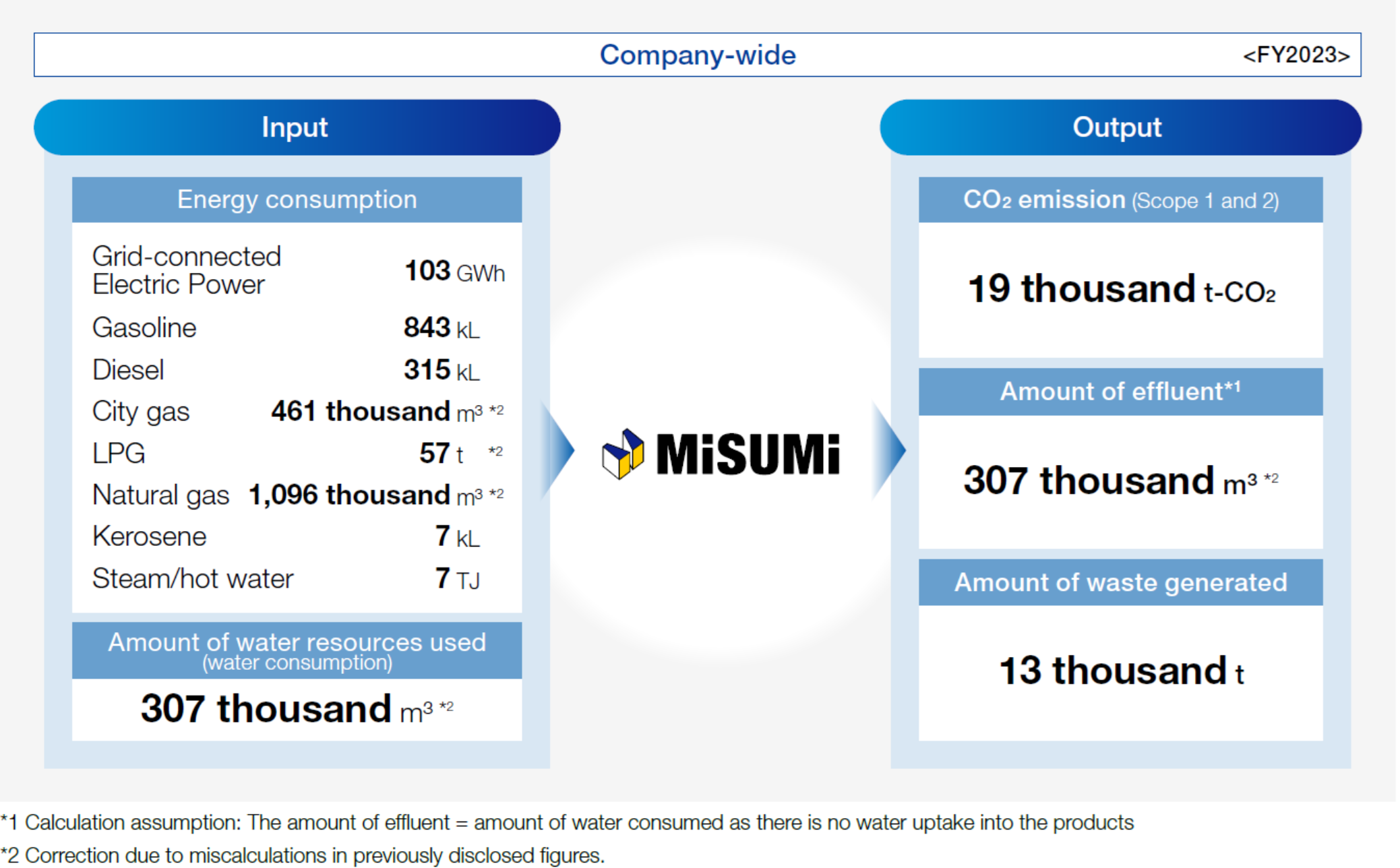

Business Activities and Environmental Impact (Material Balance)

Business Activities and Environmental Impact (Material Balance)

MISUMI Group represents environmental inputs and outputs related to our business activities in the form of a material balance. This also includes water-related data, providing information on both amount of water intake and effluent produced.

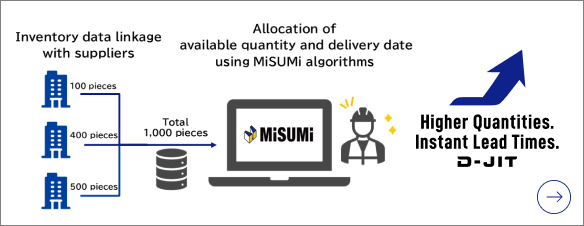

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.